In the world of advanced manufacturing, choosing the right molding process can make or break a project. Insert molding and overmolding are two popular injection molding techniques that combine materials to create high-quality, durable parts. While both processes share similarities, they serve distinct purposes and offer unique advantages. This article provides a comprehensive comparison of insert molding and overmolding, exploring their processes, benefits, limitations, and key metrics to help manufacturers, engineers, and procurement managers decide which method best fits their project needs. Whether you're designing automotive components, medical devices, or consumer products, understanding these processes is critical for optimizing cost, efficiency, and performance.

Insert molding is a versatile manufacturing technique that integrates plastic with non-plastic materials, such as metal or ceramic, to create a single, cohesive part. Widely used across industries like automotive, medical, and electronics, insert molding streamlines production and enhances part functionality.

Insert molding is a single-step injection molding process. It begins with the placement of a pre-made insert—typically made of brass, steel, stainless steel, or even another plastic—into a mold cavity. This insert can be placed manually or automatically, depending on the production setup. Once the insert is positioned, molten plastic (often thermoplastics like nylon or polyethylene) is injected into the mold, encapsulating the insert. As the plastic cools and solidifies, it forms a strong bond with the insert, creating a unified component. The final part is ejected from the mold using ejector pins, ready for immediate use or further processing.

Key features of insert molding include its ability to combine dissimilar materials (e.g., metal and plastic) in one step, precise alignment of inserts, and compatibility with a wide range of materials, including thermoplastics, thermosets, and elastomers. The process eliminates the need for secondary assembly steps, such as soldering or adhesives, resulting in a robust, integrated part.

Benefits:

Reduced Assembly Costs: By creating a single part in one step, insert molding eliminates the need for additional assembly processes, saving time and labor costs.

Lightweight and Compact Parts: Replacing heavy fasteners with lightweight plastics reduces the overall weight and size of components, ideal for industries like automotive and aerospace.

Enhanced Reliability: The strong bond between the insert and plastic ensures durability, withstanding vibration, shock, and heavy loads.

Design Flexibility: Insert molding supports complex geometries and material combinations, allowing for innovative product designs.

Limitations:

Insert Placement Precision: Incorrect placement of inserts can lead to defects, requiring careful mold design and operator skill.

Material Compatibility: Not all materials bond well, and selecting the right combination is critical to avoid weak bonds or warping.

Higher Initial Tooling Costs: Custom molds for insert molding can be expensive, especially for low-volume production.

Overmolding is another injection molding technique that enhances parts by adding a layer of material—typically a soft, rubber-like plastic—over an existing substrate. It is commonly used to improve grip, aesthetics, or protection in products like power tools and medical devices.

Overmolding is a two-step process. First, a base component (the substrate) is created using injection molding or another method. This substrate, often a rigid plastic or metal, is then placed into a second mold. A second material, usually a thermoplastic elastomer (TPE) or soft-touch plastic, is injected over the substrate, forming a thin, flexible layer. This layer bonds to the substrate as it cools, creating a finished part with enhanced properties, such as a comfortable grip or shock resistance. The process requires precise mold alignment to ensure the overmolded layer adheres properly without gaps or defects.

Key features of overmolding include its ability to add tactile or protective layers, support for multi-material designs, and compatibility with automated production systems. The process is ideal for applications requiring ergonomic enhancements or environmental protection.

Benefits:

Improved Ergonomics: Overmolding adds soft, grippy surfaces, enhancing user comfort in products like toothbrushes or tool handles.

Enhanced Protection: The overmolded layer shields components from shock, vibration, and moisture, extending product lifespan.

Aesthetic Versatility: Overmolding allows for vibrant colors and textures, improving the visual appeal of products.

Multi-Material Functionality: Combining rigid and flexible materials enables unique functional properties, such as sealed enclosures for electronics.

Limitations:

Increased Production Time: The two-step process takes longer than insert molding, increasing cycle times.

Higher Costs: Additional molding steps and specialized materials can drive up production costs, especially for small runs.

Complex Mold Design: Overmolding requires precise mold alignment, which can complicate tooling and increase upfront costs.

Material Bonding Challenges: Poor material compatibility can lead to delamination or weak bonds between layers.

| Category | Insert Molding | Overmolding |

| Definition | Combines plastic with a non-plastic insert (e.g., metal, ceramic) to form a single part. | Adds a second material (usually soft plastic) over an existing molded or manufactured substrate. |

| Process Type | Single-step injection process. | Two-step process: first mold the substrate, then overmold with a second material. |

| Materials Used | Inserts: metal, ceramic, other plastics. Mold: thermoplastics, thermosets, elastomers. | Substrate: rigid plastic or metal. Overmold: soft thermoplastics or elastomers (e.g., TPE). |

| Key Features | - Combines dissimilar materials- Precise insert placement- Strong insert-to-plastic bond | - Enhances ergonomics or protection- Multi-material layering- Compatible with textured/aesthetic finishes |

| Typical Applications | Automotive connectors, threaded inserts, surgical tools, sensors | Toothbrushes, power tool handles, medical grips, rugged electronics |

| Main Benefits | - Reduces assembly steps and cost- Creates lightweight, compact parts- Provides structural reliability- Supports complex insert geometries | - Improves grip and comfort- Adds shock, moisture, and vibration protection- Enhances aesthetics- Enables sealed and ergonomic designs |

| Main Limitations | - Requires precise insert placement- Higher tooling cost- Material bonding challenges with some plastics | - Longer cycle times- Higher production cost- Complex mold design- Risk of poor layer adhesion due to material incompatibility |

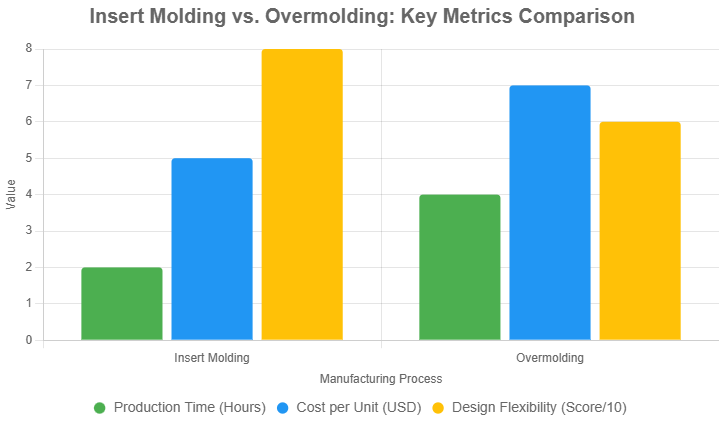

To choose between insert molding and overmolding, manufacturers must evaluate key metrics like cost, production time, and design flexibility. These factors directly impact project timelines, budgets, and product performance.

Insert Molding:

Cost: Insert molding is generally more cost-effective, with an estimated cost per unit of $5 for standard parts, due to its single-step process. The elimination of secondary assembly reduces labor and material costs.

Production Time: The single-step process is faster, typically requiring 2 hours per cycle for small to medium parts. Automated insert placement further streamlines production.

Overmolding:

Cost: Overmolding is more expensive, with an estimated cost per unit of $7, due to the two-step process and specialized materials like TPEs. Additional labor and mold changes contribute to higher costs.

Production Time: The two-step process increases cycle times, often taking 4 hours or more per cycle, especially for complex parts requiring precise alignment.

Insert Molding:

Design Flexibility: Insert molding offers high design flexibility (rated 8/10), allowing manufacturers to combine diverse materials like metal and plastic. This enables complex geometries and functional parts, such as threaded inserts or electrical connectors.

Applications: Common in automotive (e.g., dashboard clips), medical (e.g., surgical tools), and electronics (e.g., conductive plugs). It excels in applications requiring structural integrity and lightweight designs.

Overmolding:

Design Flexibility: Overmolding has moderate design flexibility (rated 6/10), focusing on adding a protective or tactile layer. It is less versatile for combining dissimilar materials but ideal for ergonomic enhancements.

Applications: Widely used in consumer products (e.g., toothbrush handles), power tools (e.g., grips), and medical devices (e.g., sealed enclosures). It prioritizes user experience and environmental protection.

Production Time: Insert molding is a single-step process, typically faster (e.g., 2 hours) than overmolding, which requires two steps (e.g., 4 hours).

Cost per Unit: Insert molding is generally more cost-effective (e.g., $5/unit) due to fewer steps, while overmolding's additional molding cycle increases costs (e.g., $7/unit).

Design Flexibility: Insert molding scores higher (8/10) for its ability to combine diverse materials (e.g., metal and plastic), while overmolding (6/10) focuses on adding a protective or textured layer, limiting material combinations.

Selecting between insert molding and overmolding depends on your project's goals, budget, and performance requirements. Below are guidelines to help you decide when each process is the best fit.

Insert molding is ideal for projects that prioritize:

Cost and Speed: Choose insert molding for cost-sensitive projects or tight production schedules, as its single-step process reduces costs and cycle times.

Structural Integrity: Use insert molding when combining metal and plastic to create strong, lightweight parts, such as automotive fasteners or medical device components.

Complex Material Combinations: Opt for insert molding when your design requires integrating dissimilar materials (e.g., steel inserts in plastic housings) for enhanced functionality.

High-Volume Production: Insert molding's efficiency makes it suitable for large-scale production runs where minimizing assembly steps is critical.

Example: A manufacturer producing automotive dashboard clips might choose insert molding to embed metal inserts in plastic, ensuring strength and reducing weight without additional assembly.

Overmolding is the better choice for projects that require:

Ergonomic or Aesthetic Enhancements: Use overmolding to add soft, grippy layers to products like tool handles or consumer electronics, improving user comfort and visual appeal.

Environmental Protection: Choose overmolding for parts exposed to moisture, vibration, or shock, such as sealed medical device enclosures or weather-resistant connectors.

Small to Medium Runs: Overmolding is suitable for projects where the added cost of a two-step process is justified by the need for specialized features like grip or insulation.

Tactile Functionality: Opt for overmolding when the product requires a specific texture or flexibility, such as a rubberized coating on a power tool.

Example: A company designing a vibrating toothbrush might use overmolding to add a soft, rubber-like grip over a rigid plastic handle, enhancing user comfort and protecting internal electronics.

Insert molding and overmolding are powerful injection molding techniques that cater to different manufacturing needs. Insert molding excels in creating strong, lightweight parts with minimal assembly, making it ideal for cost-sensitive, high-volume projects in industries like automotive and medical. Overmolding shines in adding ergonomic or protective layers, perfect for consumer products and applications requiring enhanced user experience or durability. By comparing cost, production time, and design flexibility, manufacturers can make informed decisions to optimize their projects. For expert guidance or insert molding services, contact a trusted provider like Green Vitality Industry to explore tailored solutions for your manufacturing needs.